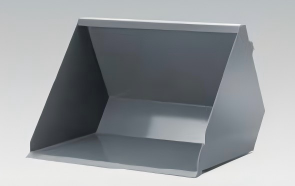

Light Bucket

The product is a Light Bucket (Smoothing Bucket), a specialized attachment for loaders and earthmoving machinery. It features a robust gray high-strength steel structure with a flat, wide base and sloped sidewalls, engineered for tasks like leveling surfaces, pushing bulk materials, and light grading. The bucket’s design prioritizes stability and even material distribution, making it a go-to tool for precision ground preparation and material handling.

Description

Product Description

Constructed from abrasion-resistant, high-tensile steel, the Light Bucket boasts a durable build that withstands the friction and impact of pushing against soil, gravel, and other abrasive materials. Its flat bottom edge is precision-machined to ensure consistent contact with the ground, while the sloped sidewalls prevent material buildup and allow for smooth pushing or scooping action. The bucket integrates with loaders via standardized quick-attach interfaces, enabling seamless connection to various machinery models. This compatibility, combined with the bucket’s hydraulic-driven tilting capability, allows operators to adjust the bucket angle precisely for different tasks, from fine grading to bulk material transport.

Application Fields

1. Construction Industry

In construction, Light Buckets are essential for site preparation and ground leveling. When building residential foundations, they smooth out excavated soil to create a stable base for concrete pouring. During road construction, they grade subgrades and spread aggregates like gravel or sand, ensuring a uniform surface before asphalt or concrete paving. For landscaping projects, such as creating lawns or garden beds, the bucket levels soil, removes bumps, and distributes topsoil evenly, laying the groundwork for aesthetically pleasing and functional outdoor spaces.

2. Agriculture and Farming

Agricultural operations rely on Light Buckets for tasks like field leveling, pasture maintenance, and crop bed preparation. In row-crop farming, the bucket levels soil to create uniform planting beds, ensuring consistent seed depth and crop growth. For livestock farms, it smooths out pasture areas, removes ruts from tractor traffic, and spreads manure or compost as fertilizer. During land reclamation projects, such as converting fallow land into arable fields, the Light Bucket grades uneven terrain, making it suitable for cultivation.

3. Municipal and Road Maintenance

Municipal departments use Light Buckets for road repairs, sidewalk leveling, and park maintenance. When patching potholes, the bucket levels the base material (gravel or asphalt) to ensure a smooth, durable repair. In parks and recreational areas, it grades walking paths, levels sports fields, and spreads mulch or sand. For snow removal in winter, some Light Buckets are adapted to push snow off roads and sidewalks, with their flat edge providing efficient snow displacement.

4. Material Handling and Logistics

Beyond grading, Light Buckets excel at moving bulk materials in warehouses, yards, and industrial sites. They can push pallets of goods, move loose materials like sand or gravel in open storage areas, and even assist in loading/unloading lightweight cargo. In recycling facilities, the bucket pushes recyclable materials (e.g., plastic bottles, cardboard) into sorting areas, streamlining the processing workflow.

Product Features

1. Precision Leveling Capability

The Light Bucket’s defining feature is its flat bottom edge, which ensures consistent contact with the ground. This allows operators to achieve millimeter-level precision when grading surfaces, a critical requirement for projects like foundation preparation or sports field construction. The bucket’s ability to maintain a uniform height reduces the need for secondary manual leveling, saving time and labor.

2. Robust and Wear-Resistant Construction

Made from heavy-duty steel with reinforced edges and welds, the bucket withstands the abrasiveness of rocks, gravel, and concrete. The flat edge is often treated with hard-facing materials (e.g., weld-on wear plates) to extend its lifespan, even under continuous use in harsh conditions like rocky construction sites.

3. Versatile Material Handling

While optimized for leveling, the bucket also functions as a general-purpose handler for bulk materials. Its sloped sidewalls allow it to scoop and transport soil, sand, or gravel, making it a dual-purpose tool for grading and material movement. This versatility eliminates the need for separate attachments, reducing equipment costs and downtime.

4. Universal Compatibility

Equipped with industry-standard quick-attach systems, the Light Bucket is compatible with most loader models, from compact skid steers to large wheel loaders. This compatibility ensures that it can be deployed across different machinery fleets, adapting to the specific needs of various projects.

5. Efficient Operation and Fuel Savings

The bucket’s design minimizes resistance when pushing or scooping materials, reducing the load on the host machine’s engine. This translates to lower fuel consumption and reduced wear on machinery components. In large-scale grading projects, this efficiency results in significant operational cost savings over time.

6. Safety and Stability

The bucket’s balanced weight distribution and low center of gravity enhance the host machine’s stability during operation, even when working on uneven terrain. This reduces the risk of tipping, a critical safety feature in construction and agricultural settings. Additionally, the bucket’s smooth edges and rounded corners minimize the risk of damage to surfaces or materials during grading.

In conclusion, the Light Bucket is a versatile, durable, and efficient attachment that plays a pivotal role in ground preparation, material handling, and maintenance across construction, agriculture, and municipal sectors. Its precision leveling capability, robust construction, and dual functionality make it an indispensable tool for achieving smooth, uniform surfaces and moving bulk materials with ease. Whether leveling a construction site, preparing farmland, or maintaining urban infrastructure, this attachment delivers reliable performance, operational safety, and cost-effectiveness, solidifying its status as a fundamental component in modern earthmoving and material-handling operations.