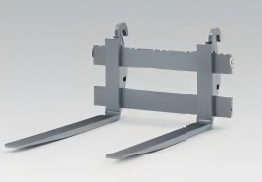

Pallet Forks

Flat Pallet Forks, a specialized attachment for material handling equipment such as loaders and forklifts. Manufactured from high-strength gray steel, it consists of two straight fork arms and a robust connecting frame. It can be quickly adapted to the host machine via standardized interfaces, and is used for stably forking, transporting palletized goods, wooden boxes, steel, and other regular loads. It is a core tool for efficient material loading and unloading in warehousing, manufacturing, construction, and other fields.

Description

Product Description

Flat Pallet Forks, a specialized attachment for material handling equipment such as loaders and forklifts. Manufactured from high-strength gray steel, it consists of two straight fork arms and a robust connecting frame. It can be quickly adapted to the host machine via standardized interfaces, and is used for stably forking, transporting palletized goods, wooden boxes, steel, and other regular loads. It is a core tool for efficient material loading and unloading in warehousing, manufacturing, construction, and other fields.

Application Fields

1. Warehousing and Logistics Industry

In e-commerce warehouses and logistics distribution centers, flat pallet forks work with forklifts to efficiently handle palletized parcels and cargo boxes, enabling rapid sorting, storage, and dispatch of goods. For example, during e-commerce peak seasons with massive orders, flat pallet forks can quickly pick up entire pallets of products, significantly improving warehouse turnover efficiency and reducing the time cost of manual sorting.

2. Manufacturing Sector

In internal material flow within factories, flat pallet forks are used to handle raw material pallets (such as chemical raw material pallets, auto parts pallets), semi-finished or finished product pallets. Taking auto parts production as an example, flat pallet forks can transport pallets of engines, gearboxes, and other components from the storage area to the production line, ensuring the continuity of material supply for the production process and avoiding production halts due to material shortages.

3. Construction Scenarios

On construction sites, flat pallet forks transport pallets of building materials such as bricks, steel bars, and pipes. In the construction of high-rise residential buildings, flat pallet forks cooperate with loaders to transfer entire pallets of bricks from the ground to the construction floors. Compared with manual handling, this not only increases efficiency several times but also reduces the labor intensity of workers and ensures the safety of material transportation.

4. Retail and Wholesale Industries

In large supermarkets and building materials wholesale markets, flat pallet forks are used to handle entire pallets of goods (such as appliance pallets, tile pallets, grain and oil pallets) to achieve rapid stocking and replenishment. Taking the building materials market as an example, flat pallet forks can transport entire pallets of tiles from the warehouse directly to the store display area, reducing losses from unpacking and secondary handling, and improving the efficiency of the sales process.

Product Features

1. High-Strength Structure, Reliable for Heavy Loads

Made of thickened high-strength steel, the welding process between the fork arms and the frame is precise, with excellent bending and wear resistance. It can safely handle loads of several tons (specific load capacity depends on the model). Even when handling heavy goods such as steel and stone for a long time, it can maintain structural stability and is not easily deformed.

2. Straight Fork Arms, Load Protection

The fork arms are designed to be straight and have a smooth surface, providing a large contact area with the pallet, ensuring even force distribution and effectively reducing wear on pallets and goods. When handling pallets of fragile items (such as glass products) or high-precision equipment, it can minimize damage to goods caused by fork arm deformation or slipping.

3. Standardized Compatibility, Quick Switching

Equipped with industry-standard quick-connect interfaces, it can be adapted to loaders and forklifts of various brands and models. The disassembly and assembly process only takes a few minutes. In multi-task scenarios (such as simultaneously handling palletized goods and bulk goods in warehousing), it can quickly switch between flat pallet forks and other attachments (such as grapples, buckets), enhancing the versatility of the equipment.

4. Efficient Operation, Safe and Stable

When picking up goods, the straight fork arms can be accurately inserted into the pallet slots. During transportation, the load center of gravity is stable, reducing the risk of goods tilting or falling. Operators can realize precise lifting and moving of the fork arms through the hydraulic or mechanical control system of the host machine, and can work efficiently even in narrow passages.

5. Simple Maintenance, Controllable Cost

The structure is simple, without complex transmission components. Routine maintenance only requires checking the wear degree of the fork arms and whether the fasteners at the connection parts are loose. Worn fork arms can be replaced individually without overall scrapping, greatly reducing the maintenance cost during long-term use, which is suitable for the cost control needs of small and medium-sized enterprises.

In summary, with its high strength, high compatibility, and efficient operation capabilities, flat pallet forks have become a fundamental and key attachment in the material handling field. They play an irreplaceable role in improving the material flow efficiency of warehousing, manufacturing, construction, and other industries, and are one of the core tools for achieving "efficient handling and safe flow" of goods.