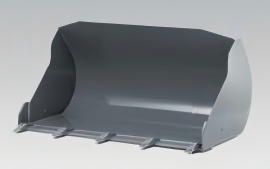

Description

Application Fields

1. Mining and Quarrying

In the mining and quarrying industries, the rock bucket is an indispensable asset for primary material handling. It is deployed to load and transport vast quantities of raw, unprocessed materials directly from the extraction face. In a granite or limestone quarry, for instance, it is used to efficiently scoop, segregate, and load massive, irregularly shaped rock blocks and boulders onto heavy-duty haul trucks for transport to the primary crusher. In both open-pit and underground mining operations, its durability is crucial for handling fragmented ore, muck, and overburden, ensuring a continuous and efficient material flow from the point of extraction to the processing plant or waste dump, thereby maximizing throughput and minimizing equipment downtime.

2. Construction and Demolition

Within the construction and demolition sector, the rock bucket excels where standard buckets would quickly fail. It is the tool of choice for site development on challenging, rocky terrain, where it is used to excavate for foundations, utility trenches, and grade beams by breaking into and removing native rock. On demolition sites, it proves invaluable for sorting and loading heavy, mixed debris containing large chunks of concrete, rebar, and masonry. Furthermore, in hardscaping and landscape construction, it is used to precisely place large stones, rip-rap, and boulders for creating retaining walls, erosion control structures, and decorative features, combining brute force with a degree of material placement finesse.

3. Major Infrastructure and Heavy Civil Engineering

For large-scale infrastructure projects, the rock bucket is critical for earthworks involving rock. In the construction of dams, levees, and seawalls, it is used to move and strategically place very large rocks (rip-rap) for armoring slopes and preventing erosion from water flow and wave action. In tunnel boring and micro-tunneling projects, it handles the muck—the excavated rock and soil—clearing the face and loading it for removal. In river restoration and channelization projects, it positions boulders and gabion stones to create hydraulic structures, stabilize banks, and form natural fish habitats, demonstrating its role in both building and environmentally sensitive engineering.

Product Features

1. Superior Abrasion and Impact Resistance

The bucket is manufactured from premium, quenched and tempered wear-resistant steel, such as Hardox or AR400/500 plate. This specialized material provides an exceptional hardness rating, allowing it to resist grinding wear from constant contact with sharp-edged rock and gravel. Critical stress zones, including the corner braces, hinge points, and the interface between the floor and sidewalls, are fortified with additional wear plates and reinforced with continuous, high-penetration welds. This robust construction prevents cracking, metal fatigue, and deformation, even under repeated high-impact loads from dropping large rocks, ensuring an extended service life in the world's most punishing conditions.

2. High Load Capacity and Unyielding Structural Integrity

The bucket's geometry is optimized for both capacity and strength. Its deep, wide body allows it to carry a significant volume of heavy material, reducing the number of cycles required to complete a task and thereby boosting overall productivity. The foundation of this capability is the use of thickened steel plates in the bucket floor and sidewalls, which work in concert with internal stiffeners to create a rigid structure that resists bending and permanent distortion under the immense weight of dense rock loads. This integrity is critical for maintaining performance and safety when handling multi-ton loads.

3. Optimized, Replaceable Tooth System

The leading edge is equipped with an array of heavy-duty, conical or radical-lip replaceable teeth. These teeth are crafted from specially hardened alloy steel and feature an aggressive profile designed to concentrate extreme force onto a small point, facilitating easy penetration into compacted gravel piles, fractured rock, and frozen ground. They are secured with robust mechanical locking systems (e.g., pin-and-hammer) that prevent accidental loss during violent digging and prying actions. The replaceable design means that when the tips eventually wear down, they can be swapped out quickly and individually, transforming a major repair into a simple, low-cost maintenance task, thus minimizing operational downtime.

4. Universal Compatibility for Fleet Versatility

The rock bucket is designed with standardized quick-attach mounting systems, such as the universal skid-steer interface or specific excavator mounting plates. This allows for seamless integration with a wide range of host machines, from compact skid-steer loaders used in landscaping and confined sites to massive excavators deployed in mining and major civil engineering projects. This interoperability provides contractors and operators with tremendous flexibility, enabling a single attachment to be utilized across an entire fleet, adapting to the specific demands and scale of different projects without requiring specialized equipment.

5. Efficient Material Retention and Controlled Dumping

Despite its rugged appearance, the bucket's interior geometry is carefully engineered. A strategically calculated curvature and high sidewall profile work together to cradle the load during lifting and transport. This design minimizes spillage of loose, irregularly shaped rocks and gravel, ensuring that more of the collected material reaches its destination. Furthermore, the optimized breakout angle and clean internal lines facilitate a more complete and controlled dump, reducing the need for manual clearing and preventing material from sticking or bridging in the bucket, which enhances cycle times and operational efficiency.